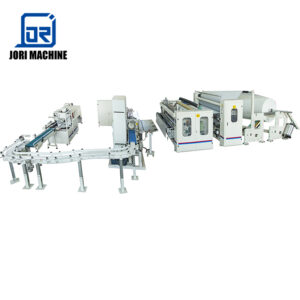

This toilet paper making production line includes the following machines:

This toilet paper making production line includes the following machines:

Features of Non-Stop Fully Automatic Toilet Paper Roll Making Production Line :

Specification of Non-Stop Fully Automatic Toilet Paper Roll Making Production Line :

| Machine type | Name | Unit | Qty | Remark | |

| Toilet tissue roll non-stop rewinder

Model:J400-2900 |

Jumbo roll

back stand unit (Ref. Parameter 4.2) |

set | 3 | Maximum jumbo roll diameter 2000mm,

Maxi weight of raw paper: 2 tons |

|

| Main machine

perforate and rewinding unit (Ref. Parameter 4.3) |

set | 1 | Max.finish roll diameter 150mm

Maximum speed 400m/min |

||

| Nested to nested lamination unit to make kitchen towels

(including two steel embossing rollers to make toilet rolls) (Ref. Parameter 4.4) |

set | 1 | Point to point dislocation glue lamination, including dust cleaning system, Steel roller diameter 495mm | ||

| Optional Parts: | Edge embossing unit | set | 1 | Not include, Add the extra cost | |

| Full embossing unit | set | 1 | Not include, Add the extra cost | ||

| Tail glue spray and sealing machine

(Ref. Parameter 4.5) |

set | 1 | Up to 25 log/min | ||

| Log Accumulator

(Ref. Parameter 4.6) |

A206 accumulator | set | 1 | A total of 206 pieces of paper was stored | |

| Cycle accumulator | set | 1 | Including two logs saw cutters distributors | ||

| Core Tube Making Part

(Ref. Parameter 4.7 & 4.8) |

Conveying and gluing device for the paper core unit | set | 1 | ||

| Paper core holder | set | 1 | Store up to 280 pc paper core | ||

| paper core machine | set | 1 | |||

| Common DC bus + motion control system | set | 1 | |||

WhatsApp us